Digital Insights for Physical Assets

How do you know if your

are functioning properly?

Real-time equipment management and alerting for your most critical, customer-facing systems.

How do you know if your

are functioning properly?

Real-time equipment management and alerting for your most critical, customer-facing systems.

Leverage real-time alerts to proactively detect issues, reduce downtime, and ensure peak performance of critical assets. Gain clarity and optimize response times across your operations.

Deploy OEM-agnostic hardware across your entire equipment portfolio with minimal disruption. Eliminate data silos, unify system visibility, and improve uptime at scale.

AI continuously analyzes operational data to identify early indicators of equipment failure. Prevent costly downtime, lower maintenance costs, and safeguard the customer experience through proactive, data-driven decisions.

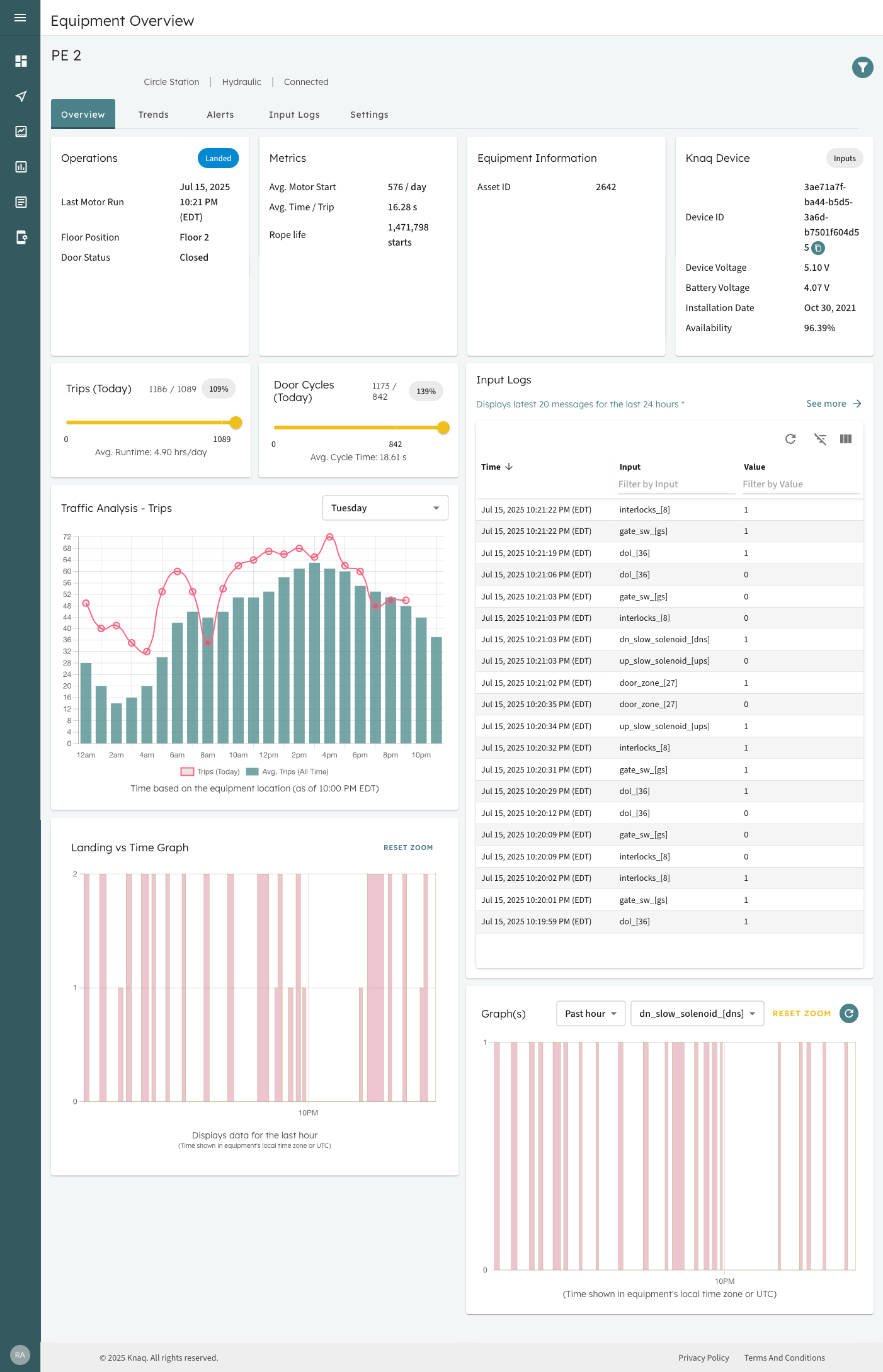

Gain complete control of your equipment portfolio with a platform built for real-time visibility and smarter decision-making.

Live alerts and intuitive dashboards keep your team one step ahead, while automated uptime reporting helps you demonstrate reliability and performance.

Predictive maintenance uses AI to surface issues before they lead to failures—reducing downtime and avoiding service disruptions.

Field techs stay connected with a mobile app that puts asset data and alerts at their fingertips, ensuring faster, more informed responses.

With a live map view of all sites, your team can quickly prioritize issues, maintain uptime, and deliver a seamless experience to your customers.

Full-portfolio visibility

Real-time alerts

Cell connectivity

Cloud-based software

Unlock data insights on physical equipment across the entire organization

Views for performance and availability data

Custom intra-building equipment status mapping

Seamless integration with your existing software tools

Exportable reports and integrations with BMS systems

AI-based predictive recommendations

“So, we have been looking for a solution to monitor elevator and escalators for a couple of years… Knaq gives us the ability to do that.”

“The email and text messaging alerts are a huge help.”

![]()

“We are finding the Knaq equipment has been an important tool in our day-to-day monitoring activities. The ability to view the dashboard on any cell phone, allows us to access equipment data anywhere and anytime.”

Monitoring SMS & Email Alerts

Daily Telemetry Messages

Support

Knaq is a vertically focused, cloud-native IoT platform that offers fully integrated hardware solutions for various equipment applications.

Knaq offers a hardware-enabled SaaS platform with unit pricing based on the number of machines monitored. Contact us for a custom quote.

Knaq generally works with asset management, operations, maintenance, or facility staff in large public and private institutions. Our primary focus is vertical transportation.

Knaq’s unique hardware portfolio is responsible for data acquisition. We leverage cellular connections to transmit this information to a central cloud ecosystem where data is analyzed, stored, and distributed back to users. Our solutions provide end-to-end functionality.

Yes! Knaq devices are completely controller and equipment agnostic, allowing for seamless plug-and-play integration regardless of the OEM. This flexibility enables you to consolidate all your equipment monitoring into a single dashboard with Knaq or utilize APIs to extract the data as needed.

Knaq’s hardware portfolio coupled with deep domain expertise in the industries we operate.